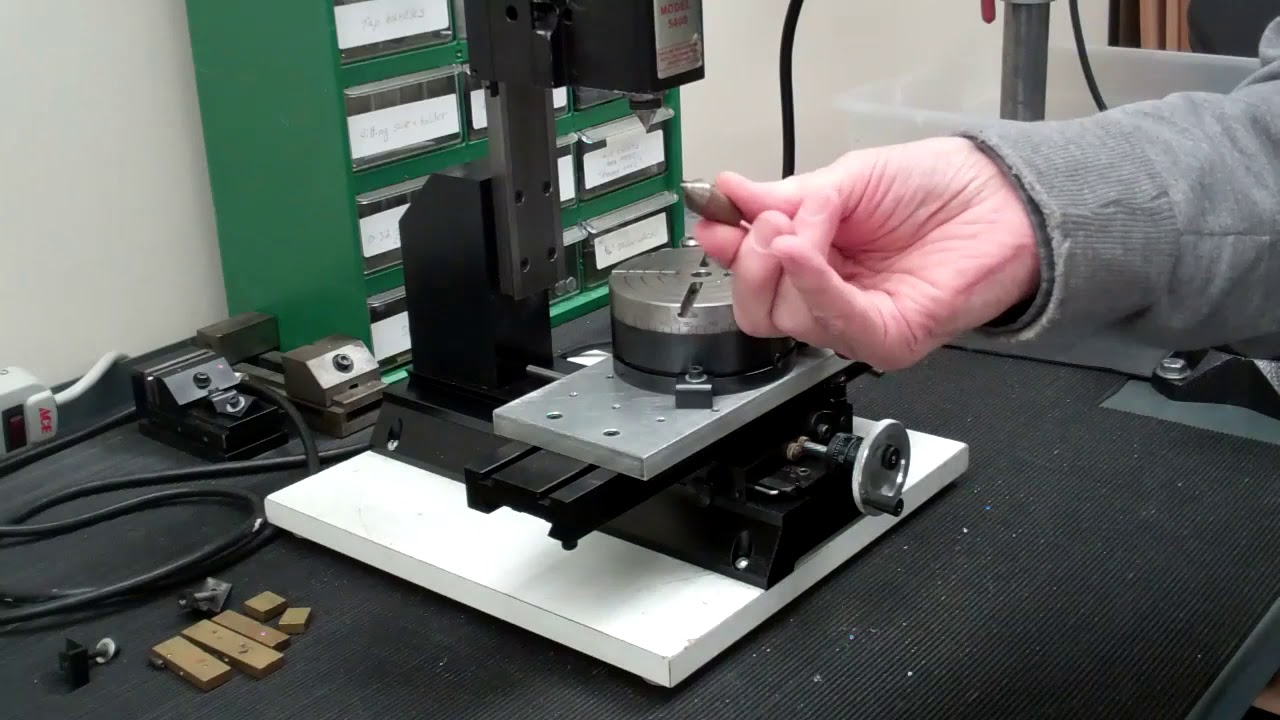

This allows the accurate machining of items like gears with odd numbers of teeth. Basic resolution is 28,800 steps per revolution, ☐.006° per step. If an error is made, previous positions can be accurately recalled by hitting another button. In the 90° position, the rotary table center is also at the 2.7″ height that allows the right angle tailstock to be used with it.Īfter entering the number of steps per revolution (or the number of degrees per step) on a simple numeric keypad, the table advances quickly and precisely to the next position at the touch of a single advance key. Tilting Angle Table-This table holds the rotary table and can be fixed at any angle from 0° to 90°. A right angle tailstock is also available to support long stock held on center in the rotary table. Right Angle Attachment-This plate holds the table in the vertical position with a center height of 2.7″. In addition, there are two options available for mounting the table in the vertical position or at other angles: The rotary table comes with clamps and T-nuts for attaching it to the T-slots of a Sherline mill table. You get everything you need including the 4″ Sherline rotary table with an installed stepper motor, microprocessor unit with numeric input keypad, 115 VAC power source, and all necessary connecting cables. Clock-makers or anyone with a need to cut gears or other complicated radially symmetrical patterns will find this accessory takes all the headaches out of repetitive indexing operations.Īll entries are made from this simple keypad. Sherline has taken their accurate and reliable 4″ rotary table into the 21st century with the addition of Computer Numeric Control. 3700-OP Rotary Table set up on a 3750 Tilting Angle Table.

NOTE: When the worm housing is reversed to the opposite side, a clockwise rotation of the handwheel or stepper motor will result in a counter-clockwise rotation of the rotary table. If you used a standard rotary table in the previously described set-up the handwheel would be mounted facing the backside of the X-axis. The reverse mount allows access to the handwheel from the front of the machine (see photo below). The reverse rotary table is perfect for using on the tilting angle table. Things that I have gotten lots of use from:ģ/8" end mill holder (and set of 3/8" mills)Īlso I really liked the videos from "" he uses an X2 mill not a fancy mill.About the CNC 4″ Rotary Table Indexer with Reverse Mount Also be realistic while a $600 vice would be great would a smaller imported one be almost as good ? My suggestion is buy tools as you need them, if you don't have a project that needs a ball end mill don't get one. So likely you will spend $300-$500 on tooling to use the mill. When you get a mill expect to spend as much on tooling as you did on the mill. I still wear hearing protection.Īnother thing that is not mentioned in many places is the larger machine, the larger the tools, the more expensive it will be. I selected a Harbor Freight "Mini-Mill" with one add on the belt drive (from ) in my mind it is a requirement, the gears are really noisy. So no knee mills that weigh 2,000+ pounds. Third was size, I needed to put in into my basement. I'm not making items that my life depends on or will be used in a commercial setting. Second was expectation, I'm not going to be making huge things, 3-6" max size, also my tolerances are not very tight. I wanted a mill that I could afford, for me that meant non-CNC and R8 tooling since there is lots of cheap tools available. There is a ton of information about getting a mill for various hobbies.

SHERLINE ROTARY TABLE DESKCNC SOFTWARE

Also, make friends with your local machinists, they will often let you on to play with their software after hours. There is also metals express (google it) and online metal supply, however shipping is a killer and aluminum prices are going through the roof. There is a local metal supplier that I use (search for alcobra metals)(call your local shops and ask if they know of any local metal reseller, they will usually sell scrap to us hobbiests) I have put probably close to 500 hours runtime on my mill in the year and a half that I have owned it.

SHERLINE ROTARY TABLE DESKCNC FREE

Alibre has a free version that is fairly powerful and getting better all the timeĪnd from you generally get ~10% off list price on taig stuff. Anyone who sets up the 3 axis setup per my setup can have my setup files for mach 3 that should get you going very quickly (other than port selection and motor tuning, that is entirely up to you)įor software, deskCNC works decently, as does visual mill and Bobcadcam depending on how much you want to shell out. This is the best priced intro desktop setup as long as you are willing to do your own initial setup.

I have a taig, the 2019CR-ER with the Xylotex 3 axis CNC board/stepper motor kit running mach 3 (I would also suggest getting the plugins for mach, as they are very handy.

0 kommentar(er)

0 kommentar(er)